Stainless pipe heat treatment line

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: ø10-120mm

Heating way: Induction heating

Product Detail

Application Video

Product Tags

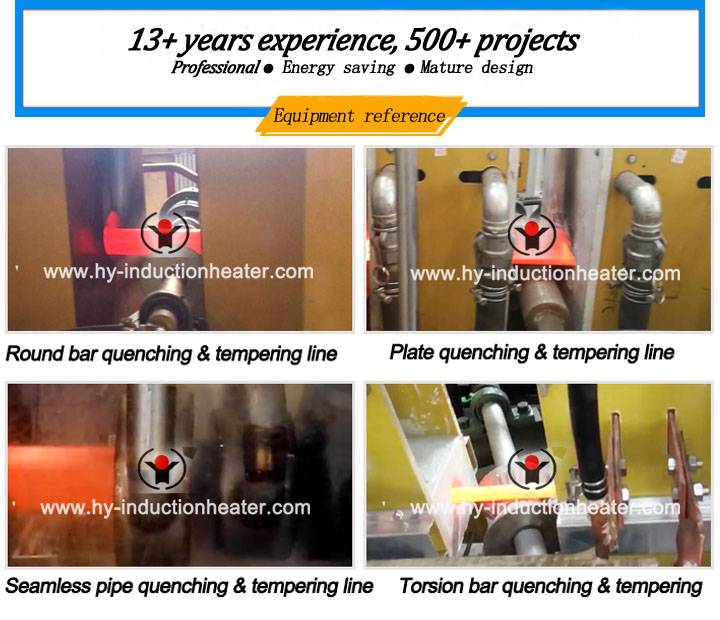

Having more than 13 years of experience in the field of induction heat treatment, Forever engineer team has rich experience for stainless pipe heat treatment line. Especially this month we sold one set of ø30-60mm stainless pipe heat treatment line for our Shanghai customer.

Stainless pipe heat treatment line

● Product Name: Stainless pipe heat treatment line,stainless pipe solution heat treatment furnace.

● Diameter range: 20mm-600mm

● Medium frequency power: 100KW-8000KW

● Product highlights: PLC automatic intelligent control, stable operation, energy saving and high efficiency,available for through quenching tempering for round bar, rods, pipes, tubes etc.

Stainless pipe heat treatment line is designed and manufactured by Forever,which has more than 20 years of experience in the area of induction heat treatment. Our sales network has covered the world, including Russia, Serbia, Argentina, Indonesia, Iran, Taiwan, Vietnam and so on.

Stainless pipe heat treatment line is suitable for the heat treatment of steel bars, rods, tubes, rods, sheets and so on.

Its characteristic is: The pipes head and pipe body has same temperature and hardness.The heating speed can be adjusted with our frequency motor.

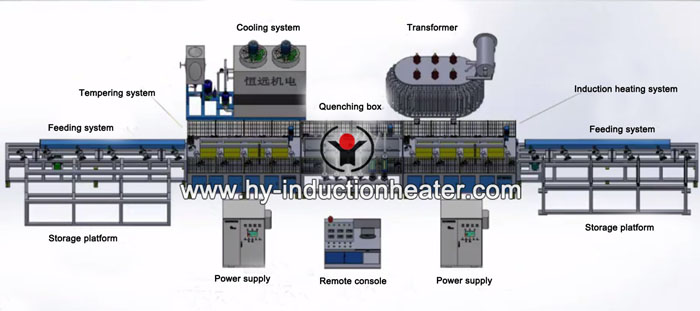

Then workers only need to put pipes on the storage platform, then all the actions will be finished under the control of PLC program control.

Stainless pipe induction heat treating configuration:

● Induction heating system (including inductor for quenching/tempering, quenching box)

● PLC console

● Mechanical transportation system

● Induction heating power supply

● Cooling tower

● Transformer

● Infrared thermometer

The core of stainless pipe heat treatment line is the induction heating power supply. The intelligent induction heating power supply is divided into IGBT induction heating power supply and KGPS induction heating power supply.

Intelligent control system

● Series resonance design, rectifying all open, high power factor and low harmonic component.

● The Power supply and induction furnace always maintain the best match and full power output. Low turn-off losses; low reactive component; low line losses; saving electricity 5%-20% compared with traditional parallel inverter power supply.

● Single or multi-frequency output, low frequency preheating, high-frequency heating-up; extreme energy-saving technology. Each ton of power consumption is 310 KW/H for heating to 1150 ℃.

● The power supply cabinet adopts T2 copper which is processed by sandblasting and passivation; low leakage inductance, antioxidant, effectively reducing line losses.

● Full touch screen control, pure digital setting, with complete process record and strict purview control.The main parameters can be one key recovery of the factory settings.

● Per single output power 50-3000KW, frequency 200-16000Hz.

If you are interested in our induction heating equipment, please send us inquiry at sales@foreverfurnace.com or call us at whatsapp +8618932783253.